Measuring recycling performance is important when you want to know how much of the waste you produce is put to good use. The range of reporting made available can seem confusing for businesses and some inside knowledge of recycling processes is often required in order to see through the smoke and mirrors. What does your recycling report really tell you?

Reporting to you

Most recycling performance reports use standard parameters such as average assumed bag and bin weights times the number of them collected in a given time frame. This simple sum doesn’t show what really happens.

After all, your recycling contains different materials and at different weights than your neighbour’s. As such these generic calculations don’t show the true story. In order to get accurate reporting its essential to do an individual waste audit to establish what materials and how much of them are in your waste. By using good quality information on what is in your waste, a varying monthly report can be produced. No one month sees you producing the same level and composition of waste and your performance levels will vary throughout the year.

How effective is my supplier?

This is an important question when you use a mixed recycling service. The materials recovery facilities (MRF) that sort your mixed recycling do so at varying levels of efficiency. Whatever they don’t separate ends up as residue (general waste) which is disposed of. Some separate as much as possible whilst others operate at the bottom of the performance scale.

How efficient a MRF operates and how good the quality of the segregated materials is, depends directly on how good the input is. Contaminating materials such as liquids, food, wood, textiles, polystyrene, sanitary tissue, etc. have a detrimental effect on this.

MRFs that receive mixed recycling with high levels of contaminants produce low quality materials for recycling. After all, that sheet of photo copy paper that got drenched with coffee or that greasy sandwich box is no good to anyone.

Low quality materials have great difficulty in finding a processor that is prepared to recycle them and often end up stockpiled or in the worst case disposed of as general waste.

Access to audit information

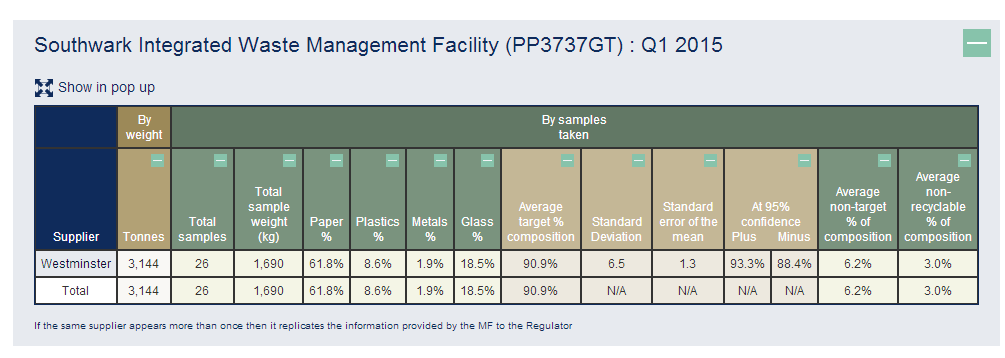

How well a particular MRF performs and how good the quality of the recycling that is delivered there by collectors is, can easily be found via the UK MRF reporting portal.

Here you can compare a range of London based recycling collectors and the MRFs they use to sort mixed recycling.

Performance and levels of contamination in the recycling differs substantially between suppliers and MRFs with up to 20% (or higher) contamination for some of them.

Where the ‘Average non recyclable % of composition’ parameter is above 15% you have to seriously ask yourself the question on whether it is worth using this supplier to collect your recycling. The loads that have produced these results contain a lot of things that should never have been in there in the first place. This greatly affects how well the segregated materials can be recycled and the quality of the materials that were separated for recycling. In the end it might do more damage than good.

In order to help you pick the right supplier to collect your waste and recycling please download our guide.